Because of its many advantages,stainless steel casting is a very effective process that is utilized in many different sectors.In comparison to conventional machine techniques,this casting production process is well known for its capacity to create parts and components with intricate shapes while providing a greater degree of design freedom.Because of its versatility,stainless steel casting can be used to create complicated designs,including parts with delicate details like threads and undercuts that are necessary for accurate fitting in a variety of applications.

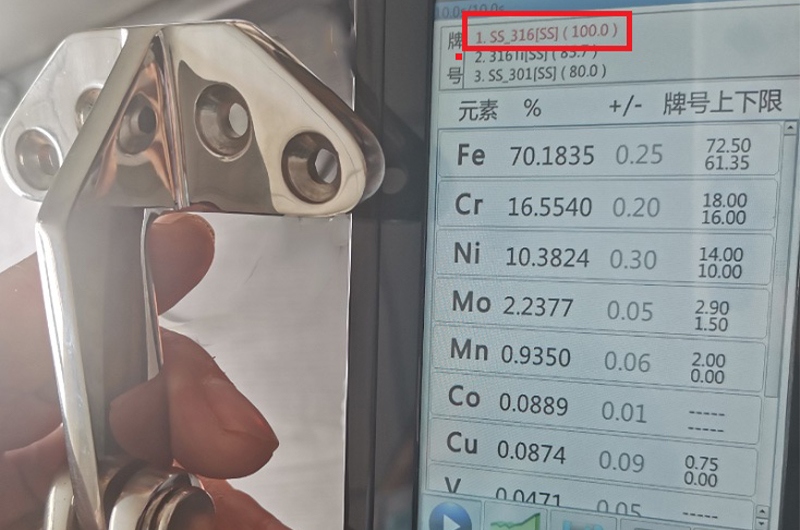

Stainless steel castings offer excellent corrosion resistance which is also one of the feature of the stainless casting parts,this is particularly important in industries exposed to corrosion environments, such as marine, medical, automotive, and food processing. The used material is directly impacts the corrosion- resistance of stainless steel castings, with higher-grade materials have higher corrosion resistance.

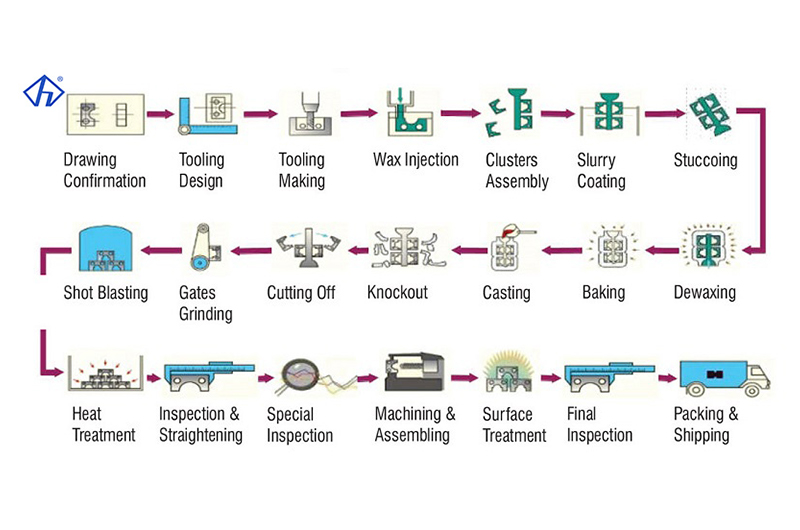

Stainless steel casting methods includes die- casting, sand-casting, and investment casting. Each method offers unique advantages,for example, investment casting is popular for producing parts with high dimensional accuracy and smooth surface. HIEVER brand precision marine-grade hardware have the advantages of this casting method, achieving high dimensional accuracy and a meticulously surface. Combined with HIEVER skilled hand-polishing, the finished hardware products achieve a mirror-like, glossy finishing.

Stainless steel casting parts have a wide applications and are the preferred material for manufacturing various products,from small to large components.In the industrial, stainless steel castings are widely used in the aerospace, construction, nuclear power, chemical, energy, and automotive industries.In short, stainless steel casting parts are widely used and have many advantages that make people choose it.

Hiever strictly controls the selection of materials and uses high-quality 316 stainless steel.In the casting process,we strictly control every procedure to minimize the error of stainless steel casting part.Due to our consummate investment casting process,our casting stainless products have a smooth surface and accurate details.You can fully trust the quality of HIEVER products,both our existing regular product and your OEM customized products!

Leave a comments