Hinge is common hardware in the market, hinge is a wide range product family that differs from material,production technology,application etc. This article is mainly about the stainless hinges with two different manufacturing process – casting and stamping.

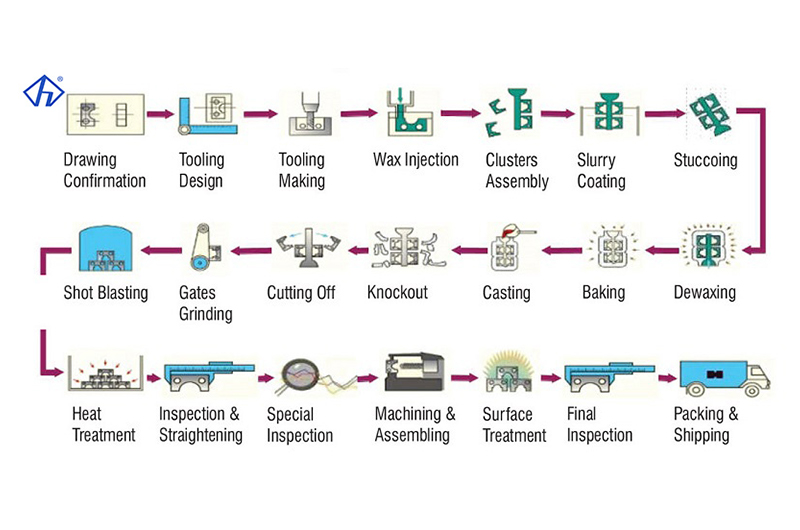

- From the processing technology, stamping hinges are made by stamping and bending metal sheets to get the hinge components for assembling as the finished hinge;casting hinges are made by pouring molten metal into a mold and then cooling it to get the hinges shape parts to assemble into one hinge.

- From the performance characteristics, stamped stainless hinges are thinner, lighter, have a smooth surface, and good toughness, but their load-bearing capacity is limited that more fragile and more susceptible to breakage due to impact.Casting stainless hinges are thicker, stronger, and have higher load-bearing capacity, stainless steel casting hinges are much strong and steady for any application occasions.

- From the perspective of applicable scenarios, stamping hinges are mostly used in daily life, such as for doors, windows, furniture, etc. Casting hinges are suitable for heavy doors, industrial equipment and other scenes with high load-bearing and wear-resistant requirements.

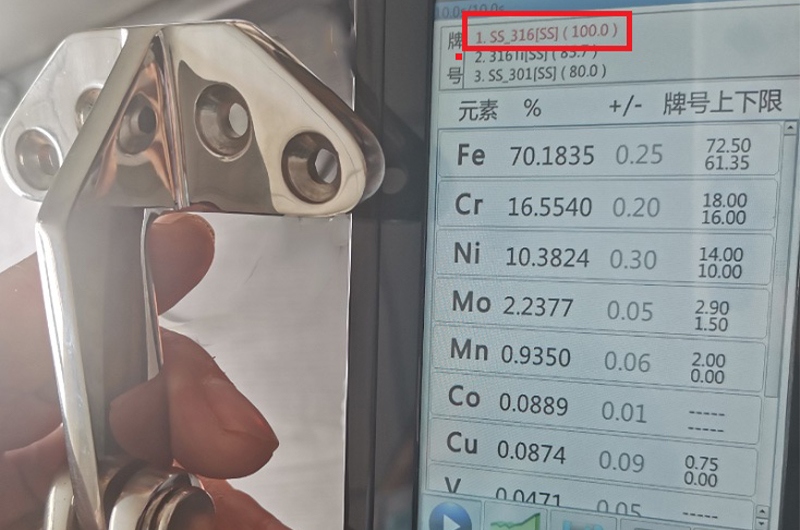

Due to the continuous advancement of investment casting technology, marine hinges are now basically casted hinges because they are highly corrosion-resistant and can be used for a long time even in the harsh environments.Marine grade hinges are also popular and required in the industries due to the advantages of the stainless steel casting process.

Hiever has hinges manufactured using two different processes,both of which are of high quality.We will recommend the stainless hinges you need based on your requirements and application situations.We mainly produce casting hinges,as they have become important marine hardware due to the continuous improvements in the marine application.

Can you guess which is the casting stainless hinge from the two photos below?

Leave a comments