Investment casting is widely used in the manufacturing industry. Compared with other casting technology, stainless precision investment casting has many outstanding superiority:

- High molding precision investment casting can produce high-precision industrial and marine hardware with smooth surface.

- Enable manufacturing Intricate industrial parts with complex shapes.If you have special OEM needs,we can customize the products you want according to your requirements.

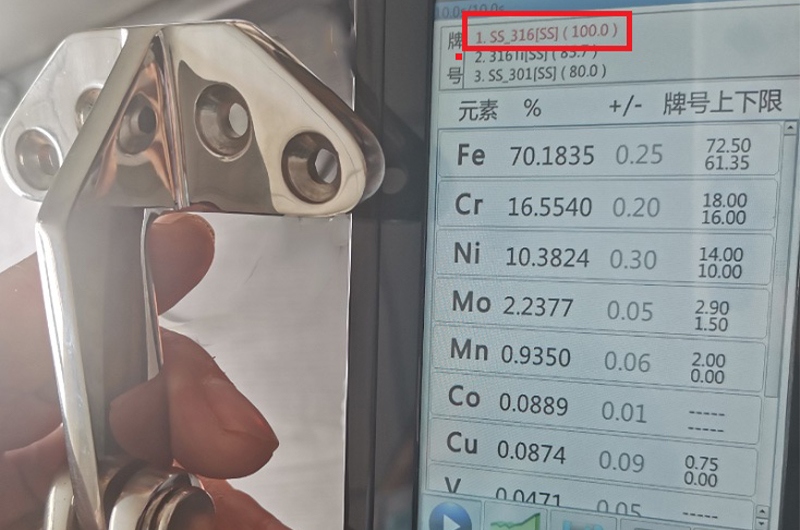

- Strong material adapt ability that investment casting materials can be stainless steel, carbon steel, aluminum alloy and other metal materials.

- High production efficiency that investment casting can achieve large-scale standardized production for mass-produced orders.

- Accurate dimension that machining is less required of the stainless steel hardware.

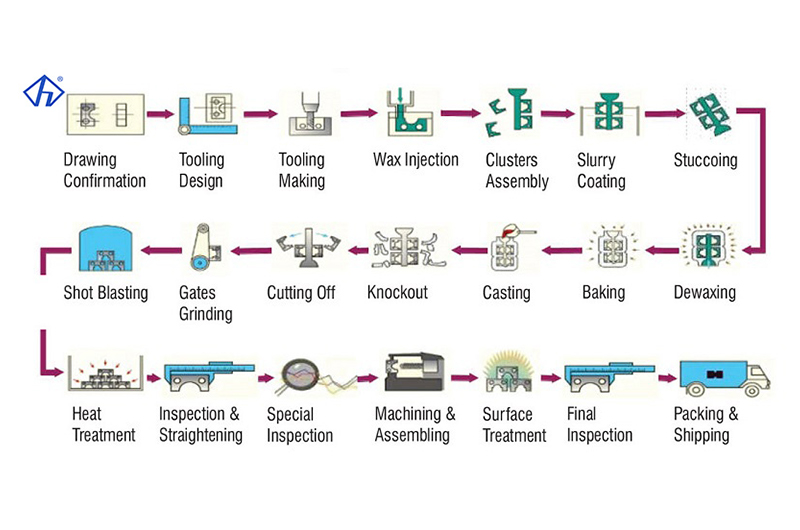

You may have questions that whether HIEVER stainless casting parts have these characteristics mentioned above? The answer is absolutely “Yes”. For high grade stainless investment parts ,you must rely on a skilled and knowledgeable investment casting factory because this is precision casting,which requires at least two weeks for mold development and at least 25 to 30 days for manufacturing.The most important fact,any mistakes made during the process will affect subsequent steps,and the damage or mistake of one process is typically irreparable which may lead to the defective products.

Hiever factory has a very complete investment casting process management to ensure the superiority of stainless investment accessories and parts,and we can ensure that our casting parts are completed within the predetermined chart. Our investment casting technology is very mature many years ,and the hardware parts produced have smooth surfaces and almost no defects.

Leave a comments