Loading

The stainless steel precision casting process uses a wax mold to form the shell, after baking, the metal liquid is poured in the mold, and finally the high-precision castings are obtained. The core features are high-precision dimensional control and high-quality surface quality. This casting process reduces machining allowances and reduces material consumption. Corrosion-resistant stainless steel parts can be used in corrosive environments such as the marine field. Our effective production and management wins the high reputation from the notable and renowned worldwide clients such as shipyard,industrial equipment manufacturer,hardware distributors etc.

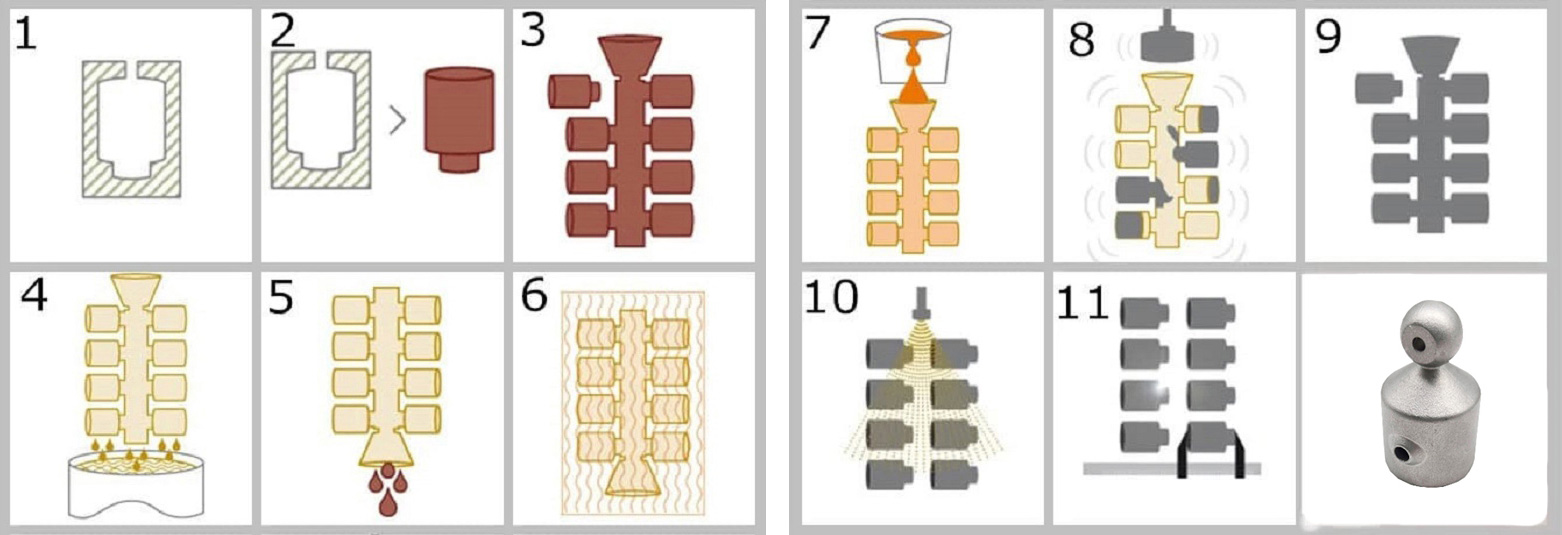

1.Production of Injection MoldMade Of Wax

A mold or matrix is necessary in order to manufacture a component using casting technology. This mould delineates the contours of the casting. Since the molding wax does not have an abrasive impact on the matrix, this matrix has a very long service life.

2.Injection Molding of Wax Pattern

Injection molding is used to replicate the future casting in wax. This requires that the injection pressure of the machine and the temperature of the molding wax are precisely coordinated in order to guarantee high dimension accuracy and surface quality of the final parts.

3.Wax Pattern Assembly

During this process, the wax pattern and sprue are assembled on frame to be a wax tree. Experienced employees meticulously assemble the wax tree to ensure high grade casting quality.

4.Wax Dipping, Sand Coating,Drying

Through repeated dipping the wax tree into ceramic slurry ,sanding, and drying process, a multi-layered ceramic shell is gradually formed. A base layer of fine silica sand is the most factor to be a very smooth casting surface.

5. Dewaxing

The wax pattern is pressure-melted from the ceramic shell in an autoclave.

6.Shell Baking

During the baking process of the ceramic shell, the wax pattern is completely burned out, leaving no residue. Firing process also solidifies the ceramic shell and imparts the required strength.

7.Pouring Casting

We mix and melt the alloy components required for each casting batch in an furnace based on the customer’s material requirements. We then ensure the molten steel meets the appropriate purity and temperature requirements before pouring it into the prepared shell. This ensures that even complex, thin-walled parts maintain high material quality and surface finish.

8.Shell Removing

After the casted mold shell cools, carefully remove casted parts from the ceramic shell housing.

9.Cutting

The casting parts are carefully cut one by one.

10.Shot Blasting

This process help removes the ceramic residue from the casting parts surface, also make the surface are suitable for the future treatment.

11.Post-Processing

These casting parts are polished,heat treated, trimmed,machined, color painting /coating according to customer specifications.

12.Final Inspection

According customer request and the parts application occasions, the quality control standards and measure is different and exclusive.We perform 100% inspection for all investment castings by hands and automatic testing equipment. We will coordinate all quality control standards and measures with customers based on their specific requirements.